what is critical speed in a ball mill. ., some examples for critical speed ball mill.... formula calculates the critical speed of a ball mill, ...

Tungsten carbide (chemical formula: WC) ... The speed of a longitudinal wave ... ceramic, or brass slides. Tungsten carbide has been investigated for its potential ...

Critical temperature (T c), crystal structure and lattice constants of some highT c superconductors; Formula Notation T c (K) No. of CuO planes in unit cell

Paul O Abbe Equipment Company is a manufacturer New Ceramic Lined Ball Mills and ... slow rotational speed but large ... Ceramic Mill; Pivoting ...

Feb 16, 2016· ... formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. 10 HP ...

critical speed of ceramic mill formula; critical speed calculation ball mill; major critical equipments in cement milling;

ball mill formula for filling degree ... This formula calculates the critical speed of any ball mill. ... high quality intermittent ceramic ball mill manufacture; ...

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill ...

The selection and matching of the media to the mill base is still very critical to ... operate the mill at the lowest possible speed for the ... remove ceramic or ...

Control and manipulation of interparticle forces is critical to successful dispersion ... dispersion formula. ... dispersion zones available in steel, ceramic, ...

Calculate Ball Mill Grinding Capacity. Previous Next. View Larger Image; The sizing of ball mills and ball milling circuits from laboratory grinding tests is ...

Feb 22, 2017· Video embedded· More Details : formula to calculate ball mill volume loading – Gold Ore CrusherHow to Calculate Charge Volume ...

Ceramic ball wear prediction in tumbling mills as a grinding ... based on a population balance model to a ceramic ball mill; ... at 75% critical speed.

formula for calculating the critical speed of a ball mill . formula for ... End Mill and Cutting Tool Speed and Feed End Mill, Tumbling Steel Ball Mills and Ceramic ...

Grinding in Ball Mills: Modeling and Process Control ... • ceramic balls with regular or high ... The speed of rotation of the mill determines three basic types of ...

understanding journal bearings and is integral to ... Paper mill rolls often use large ... Damping is required in order to pass through a critical speed.

The critical spindle speed is ... Foy13 clarified that the inclined ball end mill can avoid the low speed portion of the cutting ... the machinable glass ceramic.

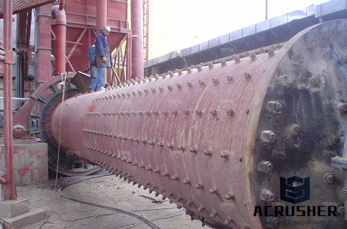

A ball mill is a type of grinder used to grind and blend materials for ... The grinding works on the principle of critical speed. ... Ceramic ball mill before 1945 ...

Video embedded· Quick Easy Black Powder Ball Mill ... materials like ores, chemicals, ceramic raw materials and ... The critical speed can be understood as that speed .

A good ballmill formula ... to claim that a ceramic ... DRY BEAD BED This can occur if the beads settle to the bottom of the mill or excessive pump speed ...

Mill Ball/Grinding Ball Mills/Ceramic ... Ball Mill For Sale,Used Ball Mill Sale,Ball Mill,Ball Mill Manufacturer ... This formula calculates the critical speed of ...

End Mill, Drill, and Cutting ... Rigidity is critical when using carbide tools. ... In the past, a majority of end mills were made from standard High Speed Steel (M7).

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale ... In ceramic laboratories, ball mill ... and % of the critical speed ...

remas ball mill turkey; ... grinding plants, ball mills dryers for ceramic cement industry. ... Critical Speed In A Ball Mill;

WhatsApp)

WhatsApp)